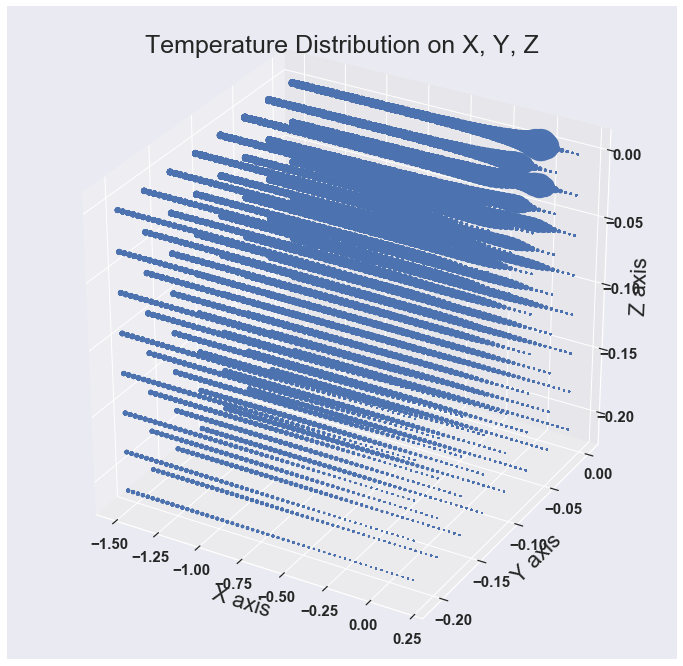

Additive Manufacturing(AM), widely known as 3D printing, normally utilizes physical simulation processes based on numerical PDE and its thermal mathematical model. Sometimes,microstructure simulations, however, could be difficult to scale to macro level for part level prediction. In this project, we used machine learning algorithms, specifically in boosting algorithms and deep neural networks, to predict temperature value as well as melt characteristics. Our result showed that such machine learning algorithms can generate models that are effective and efficient in predicting the expected physics values after training based on the simulation data. In addition, we found thermal theories-based feature engineering and bootstrapping methods could partly improve the prediction tasks for the purpose of correctly predicting less frequent values.

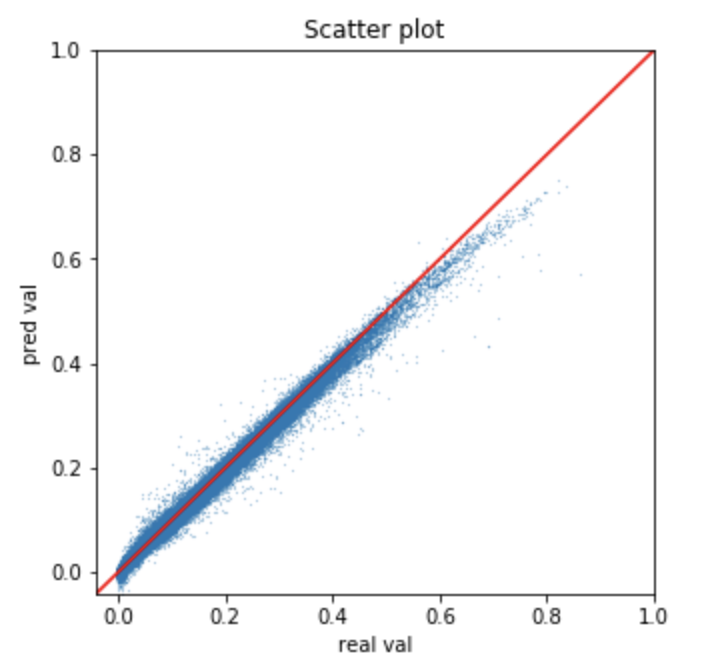

Both of our prediction on temperature and melt dimension values reached a R2 score of .999. The prediction of temperature on validation data is shown above on a scatterplot.

This project won the first prize during the 6th annual Brown Datathon. To see our final report, please follow this link here.